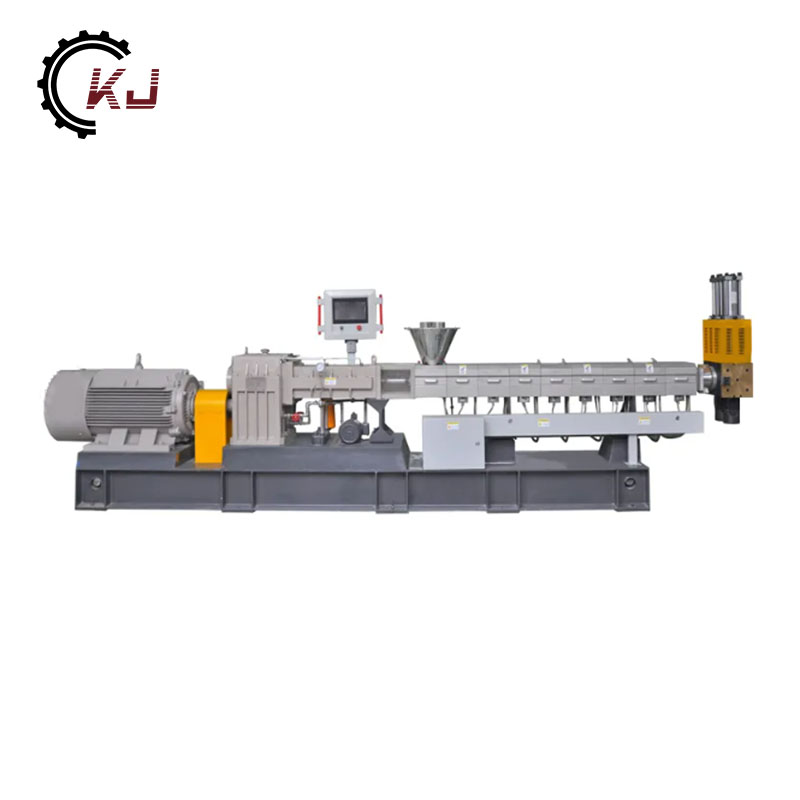

Plastic Granulator

Let us introduce you to Kangju's superior Plastic Granulator, offering you a comprehensive understanding of its capabilities. We eagerly anticipate our continued partnership with our valued customers, both new and loyal, as we work towards a shared, brighter future.

Send Inquiry

Application of raw materials:

PE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS,XPS, Stretch film, Non woven fabric, Woven bags,etc.

Flow chat of Plastic Granulator:

Water ring granulating:

Conveyor → Film compactor → Single screw extruder → Die head and hydraulic screen changer →Water ring pelletizing → Water tank → Dewatering machine → Vibration sieve → Air blower → Storage silo

Features of Plastic Granulator:

The efficient force-feeder guarantees a high-capacity feeding rate while minimizing energy usage.

The extruder of the PP/PE film pelletizing line offers both single-stage and double-stage pelletizing options.

The pelletizing method involves water-ring and water-cooling strand cutting with an extrusion mold, resulting in consistent cutting and excellent pellet shape.

Main parameters Plastic Granulator:

|

Extruder |

SJ85 |

SJ100 |

SJ130 |

SJ160 |

|

Screw diameter |

85mm |

100mm |

130mm |

160mm |

|

Main motor |

55kw |

90kw |

132kw |

160kw |

|

Compactor power |

37kw |

55kw |

75kw |

90kw |

|

Capacity |

100-180kg |

200-300kg |

300-400kg |

500-600kg |