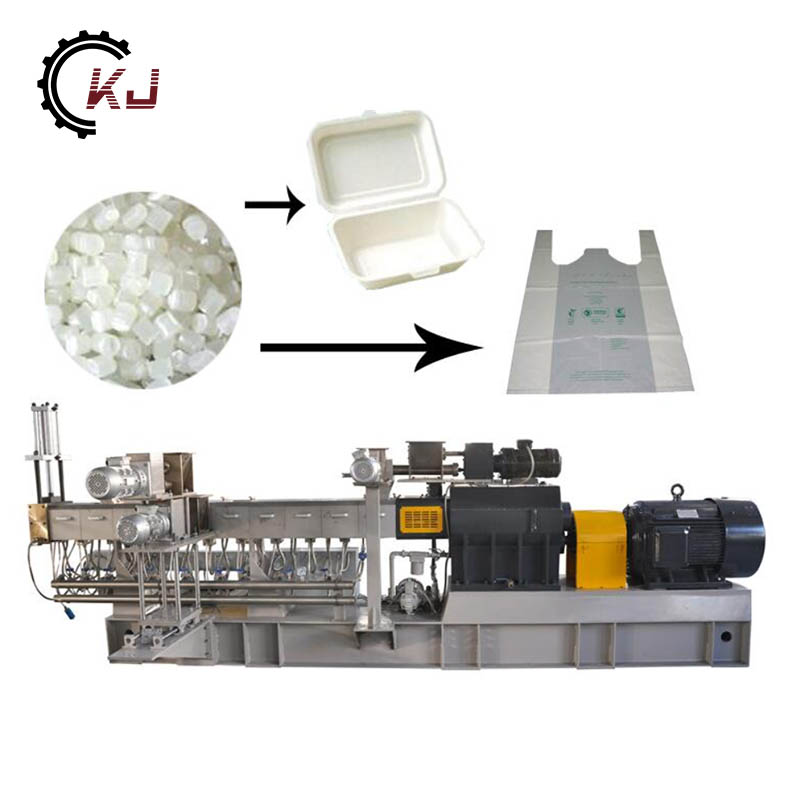

PP PE Plastic Film Waste Recycling Machine

Send Inquiry

The general description:

The plastic PP PE recycling machine washing plant is widely used to Recycle and Wash the waste PE/PP Film,Shopping bags, Woven bags, HDPE milk bottles, Rigid PE/PP containers, buckets and so on. plastic garbage recycling machine washing plant can crush, wash, dewater and dry waste PP, PE material. This is a whole production line from crushing,washing to drying the raw material.It has features as high efficiency, working stable, large capacity etc. Whatever request you have we can meet.

After washing then flakes become clean, you can make them into granules with next process which is called plastic granulator.This production line is high automatic operating and save labor cost after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. This pp pe recycling machine layout could be displayed "L" or "U" shape according clients' workshop.

Features of PP PE Plastic Film Waste Recycling Machine:

1.Material: PP PE Film/PP PE shopping Bag/PP Woven Bag/PP HDPE bottles/HDPE container/plastic buckets/ car cover/agricultural film

2.Product size: 15-20mm or customized

3.Moisture content remain: <5%

4.We can customize the recycling line according to client's requirements.

Advantages of pPP PE Film/PP PE shopping Bag/PP Woven Bag/PP HDPE bottles/HDPE container/plastic buckets/ car cover/agricultural film:

1. Final products has good quality. After washed final products plastic PP PE flakes humidity will be below 5%.

2. The whole line capacity between 200kg/h-1500kg/h.

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service life time.

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, Siemens PLC control.

Working flow of the PP PE Film/PP PE shopping Bag/PP Woven Bag/PP HDPE bottles/HDPE container/plastic buckets/ car cover/agricultural film:

Belt conveyor→2.Plastic crusher→3.Screw feeder→4.friction washer→5.Screw feeder→6.Floating washer→7.Screw feeder→8.Dewatering machine→9.Hot air drying system→10.Storage hopper→11.Control cabinet