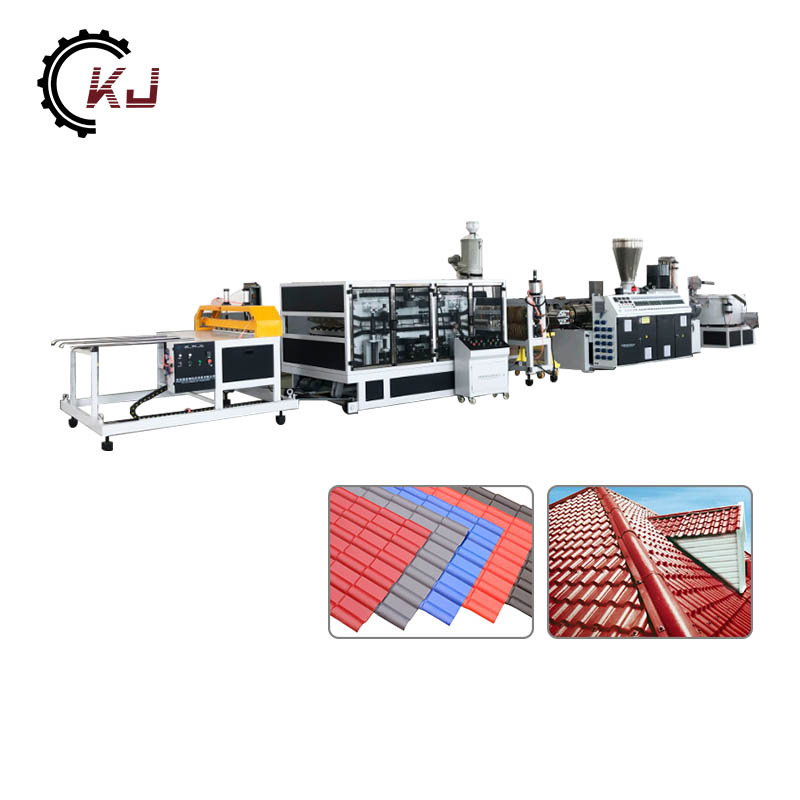

Recycle Plastic ASA PVC Roofing Tile Production Line

The Kangju Recycle Plastic ASA PVC Roofing Tile Production Line is mainly used in the production of plastic glazed tile.The plastic glazed tiles are widely used in the garden-style factory,tourist scenic spots, pavilions,hotels,family building, etc.

Send Inquiry

Recycle Plastic ASA PVC Roofing Tile Production Line Glazed Tile Extrusion Line Making Machine Glazed tile roofing sheet Applications:

The Plastic Roofing Tile Roll Forming Machine is mainly used in the production of plastic glazed tile.The plastic glazed tiles are widely used in the garden-style factory,tourist scenic spots, pavilions,hotels,family building, etc.

|

Host Model |

SJSZ-65 |

SJSZ-80 |

|||

|

The die shape |

Coat hanger style flat plate die |

Cooling die dimensions |

1300mm 600mm |

Hauling power |

1.5KW (frequency conversion)

|

|

The forming unit |

|

Cooling means |

water cooling |

Cutting means |

Shear style (pneumatic) |

|

Big wave |

R=15h=16.5 wave distance 63mm Wave distance |

Hauling velocity |

0.5-5m/min |

Cutting follow distance |

500mm |

|

Small wave |

R=9h=8 wave distance 36mm Wave distance |

Hauling roller length |

1300mm |

Work pressure |

0.4-0.6 MPa |

Feature of Recycle Plastic ASA PVC Roofing Tile Production Line Glazed Tile Extrusion Line Making Machine

Plastic sheet making machine has High capacity.

Energy saving: 20% energy saving than normal machines.

Four self-designed major core technology of sheet extruder: extrusion system, die, roller, distributor. They are all invented and designed by ourselves. The core technology has many testing points and adopts electrical integration of double protection.

The operation fully reflects the man-machine engineering principle, it can make the function more entirely and the operation more simple.

Only the tablet machine independently walking, avoid the interference from other power to influence the stability of the tabletting sheet.

The plasticizing effect of the sheet is very good. After the sheet formed and walking in curved line, it can make sure the stability of the sheet stock.

The heating system is controlled by high-grade china heater, stainless heater, inner-storing type single heating pipe and precision temperature-controlling die mould, is exact in controlling temperature, quickly in heating, good in keeping temperature, long life and save time and energy.