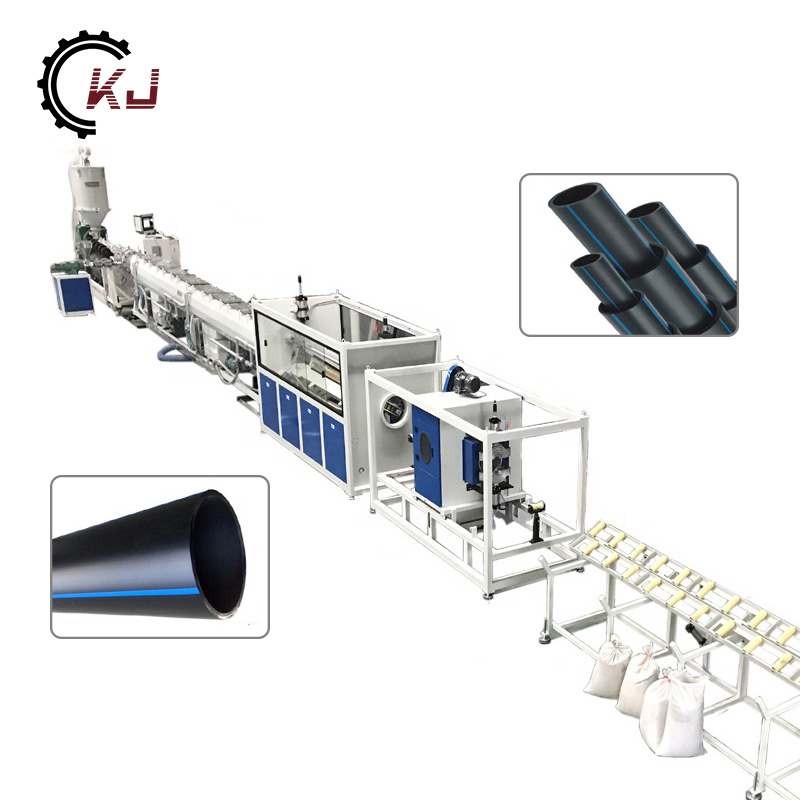

PE Sleeve Pipe Calibrator

The function of the sizing sleeve is mainly to cool down the tube blank of the PE Sleeve Pipe Calibrator, and fix the outer diameter of the tube blank and trim the surface of the tube.

Send Inquiry

PE Pipe Sleeve with Double Water Ring PE Sleeve Pipe Calibrator

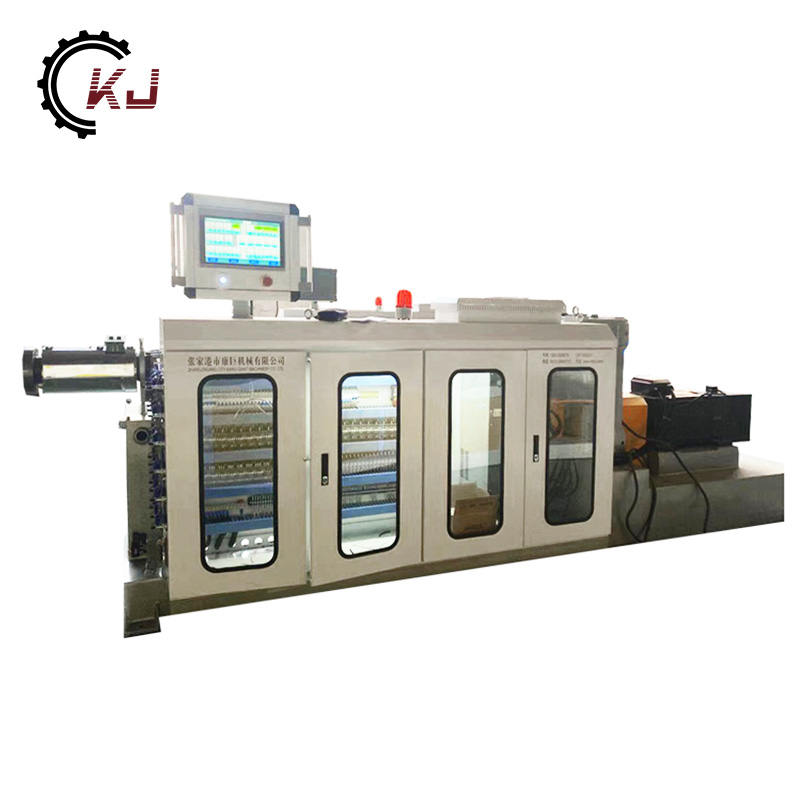

Sizing Sleeve/ Calibrator

The function of the sizing sleeve is mainly to cool down the tube blank of the extrusion die, and fix the outer diameter of the tube blank and trim the surface of the tube.

|

Sizing Sleeve Type |

Dry Type Sizing Sleeve |

Water Ring Type Sizing Sleeve |

Internal Disc Type Sizing Sleeve |

|

External Disc Type Sizing Sleeve |

Wall Thickness Adjustable Sizing Sleeve |

Outer Diameter Adjustable Sizing Sleeve |

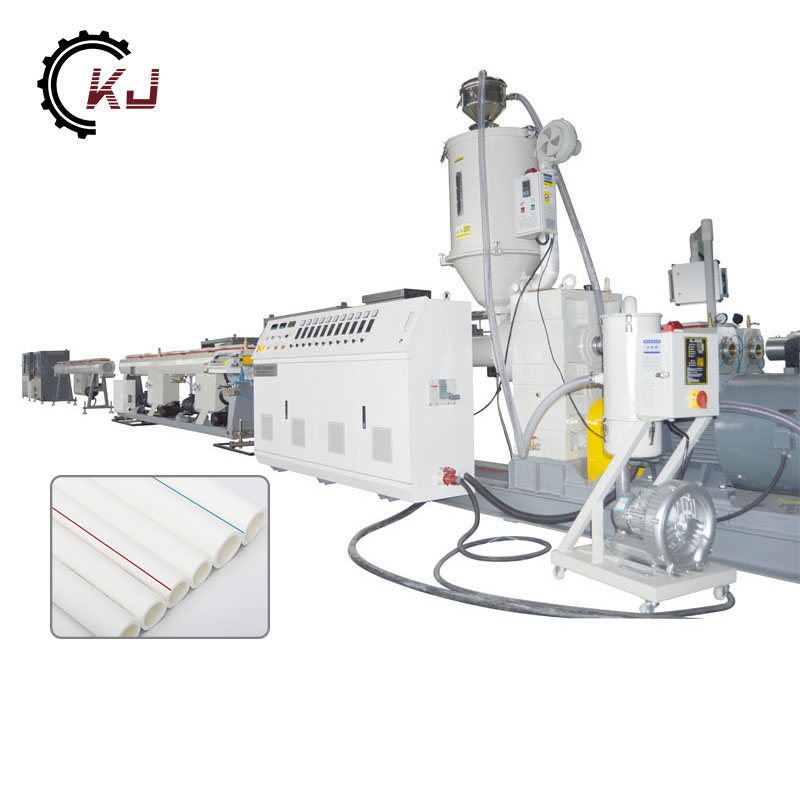

Manufacturing Process Sequence

a. Roughly machine the inner hole with Q235 thick-walled steel pipe, leaving a size allowance for the rough machining inner hole.

b. Drill through holes for true holes.

c. Weld the combined jacket and bulkhead and pipe joints of each inlet and outlet.

d. Annealing treatment to eliminate welding stress.

e. Finish turning the inner hole of the sizing sleeve and the end face of the positioning stop and the inner hole to the drawing size

Precautions for the use of sizing sleeves

a. When installing the sizing sleeve, handle it with care, and do not allow it to hit with a hand hammer to prevent the sizing sleeve from being deformed.

b. Before using the sizing sleeve, carefully clean the surface of the inner hole, burrs and dirt are not allowed.

c. When installing the sizing sleeve, pay attention to the concentricity accuracy of the inner hole of the sizing sleeve and the inner hole of the die to ensure the smooth operation of the sizing, cooling and shaping work of the extruded tube blank.