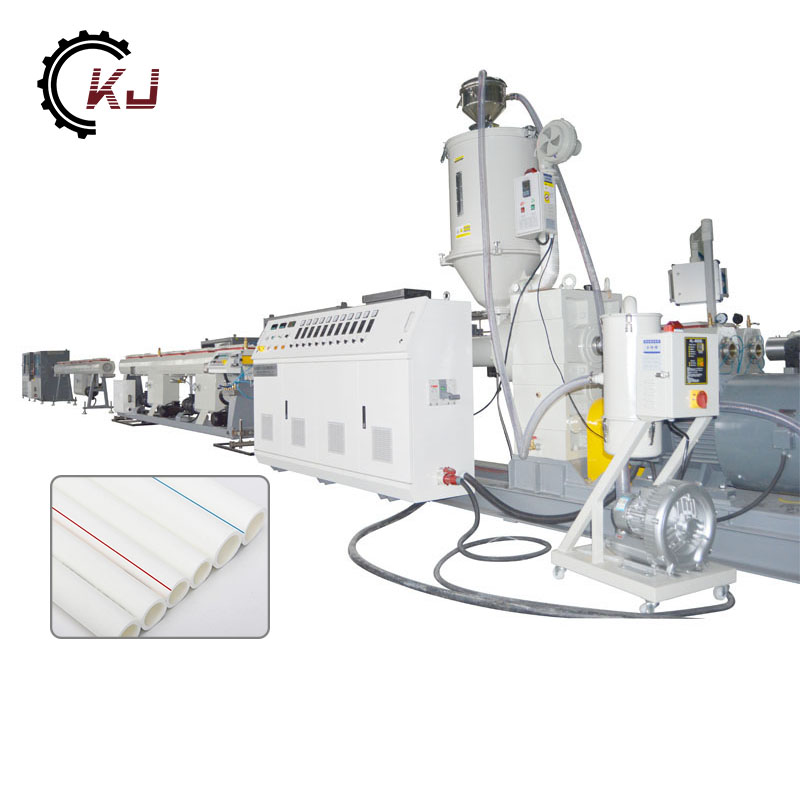

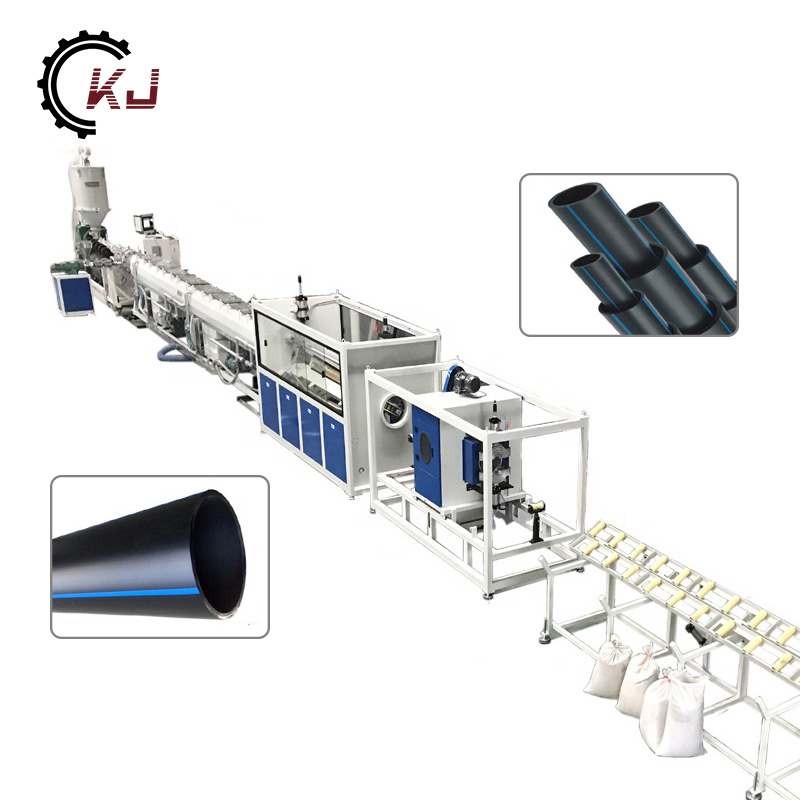

PP Plastic Water Pipe Extrusion Production Line Making Machine

This PP Plastic Water Pipe Extrusion Production Line Making Machine is used to produce PPR hot-coldwater pipe by single screw extruder.The raw material is PPR,PP, PE.The following is the introduction of high quality PP Plastic Water Pipe Extrusion Production Line Making Machine, hoping to help you better understand it. Welcome new and old customers to continue to cooperate with us to create a better future!

Send Inquiry

This PP Plastic Water Pipe Extrusion Production Line Making Machine is used to produce PPR hot-coldwater pipe by single screw extruder.The raw material is PPR,PP, PE

Process Flow of PE PP PPRpipe machine

Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → single screw extruder → color string extruder → spiral co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → spray-code printer → belt haul-off → no-dust cutter → pipe rack→finished product inspecting &packing

PP plastic water pipe extrusion production line making machine Main technical charateristics

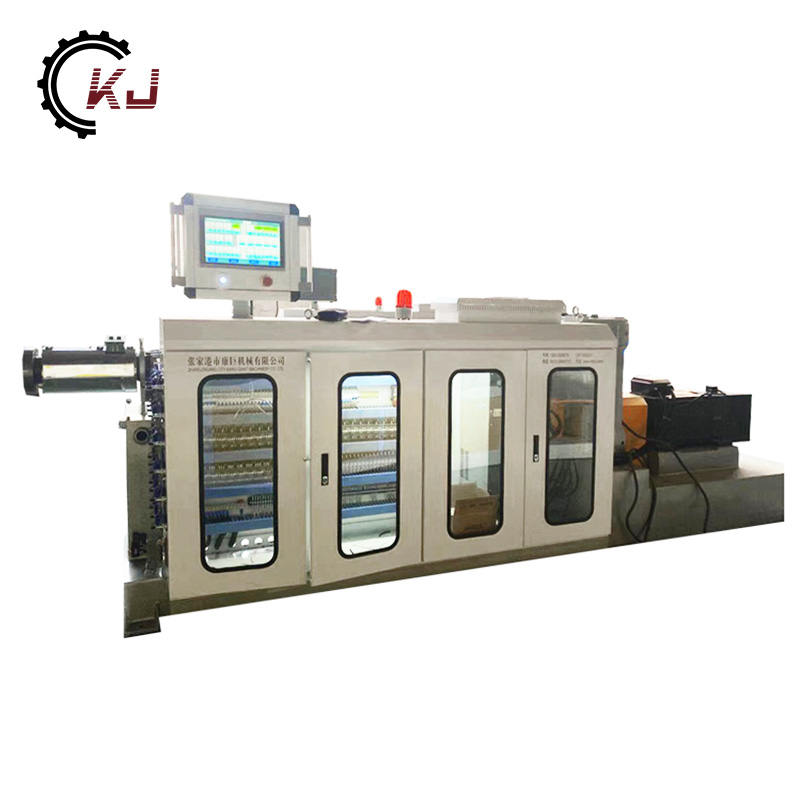

The high speed extruder adapts the optimized longer L/C ratio screw,applied on PPR,PE and formulation materialextrusion,has advantages on low wearing,low energy consumption,high efficiency,uniform and stable extrusion.

The optimized Siemens computer control system realizes the automatic control of the completely line.The top electricalpneumatic control components ensure the reliable control accuracy and service life. The special temperature control system of PID high-efficiency extruder ensures

the temperature control precision ofeach heating zone,and ensures the good finish product products.Transmission system upgraded to ensure the durability of the machine and stable production.

Main technical parameters:

|

model |

Screw parameter(mm) |

Driving power(kw) |

Heating power |

Max extrusion volume(kg/h) |

Application material |

|

EC60/38 |

60/38 |

55 |

25 |

220 |

PE/PPR/PP |

|

EC60/38 |

60/38 |

75 |

25 |

300 |

PE/PPR/PP |

|

EC60/38 |

60/38 |

90 |

25 |

360 |

PE/PPR/PP |

|

EC60/38 |

60/38 |

110 |

25 |

440 |

PE/PPR/PP |

|

EC75/38 |

75/38 |

132 |

30 |

520 |

PE/PPR/PP |

|

EC75/38 |

75/38 |

160 |

30 |

640 |

PE/PPR/PP |

|

EC90/38 |

90/38 |

250 |

42 |

1000 |

PE/PPR/PP |

|

EC90/38 |

90/38 |

280 |

42 |

1100 |

PE/PPR/PP |

|

EC120/38 |

120/38 |

355 |

56 |

1300 |

PE/PPR/PP |

PP plastic water pipe extrusion production line making machine Applications: