Wood plastic composite profile making machine

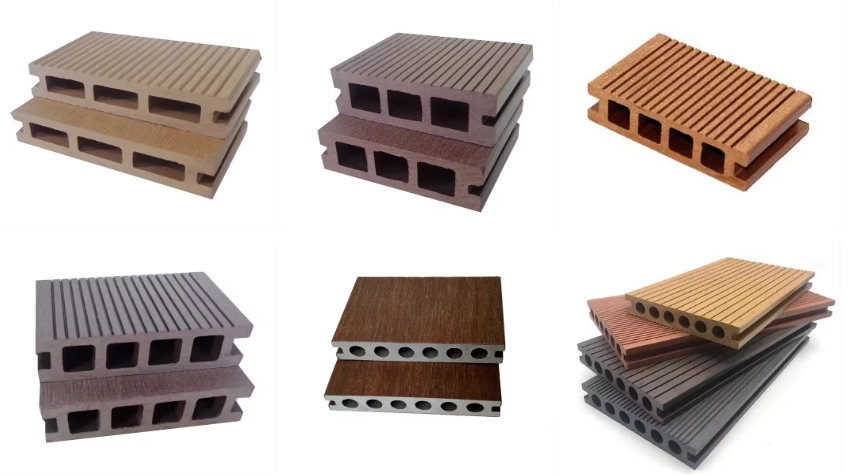

Product Description Wood plastic composite profile making machine 1. WPC floor making machine can be used to produce WPC floors, fences, gazebos, benches, trash cans, etc. 2. WPC floor making machine mainly consists of screw feeder, SJSZ65/132 conical twin-screw extruder, mold, vacuum setting table, cutting machine, and stacker. 3.By replacing different molds, the same production line can be used to produce WPC profiles.

Send Inquiry

Wood plastic composite profile making machine

Wood plastic composite floor profile making machine

1. Process flow:

a. Prepare ingredients and mix.

b. Put the uniformly mixed materials into the hopper of the extruder through the automatic screw feeder.

c. After the material put into the hopper of the extruder is melted and plasticized by the extruder, it is squeezed into the vacuum shaping device through the die head.

d. The material extruded through the extruder die is sent to the vacuum shaping device, cooled and shaped by circulating cooling water.

e. The cooled special-shaped wood-plastic panels are pulled out by the tractor and sent to the cutting machine.

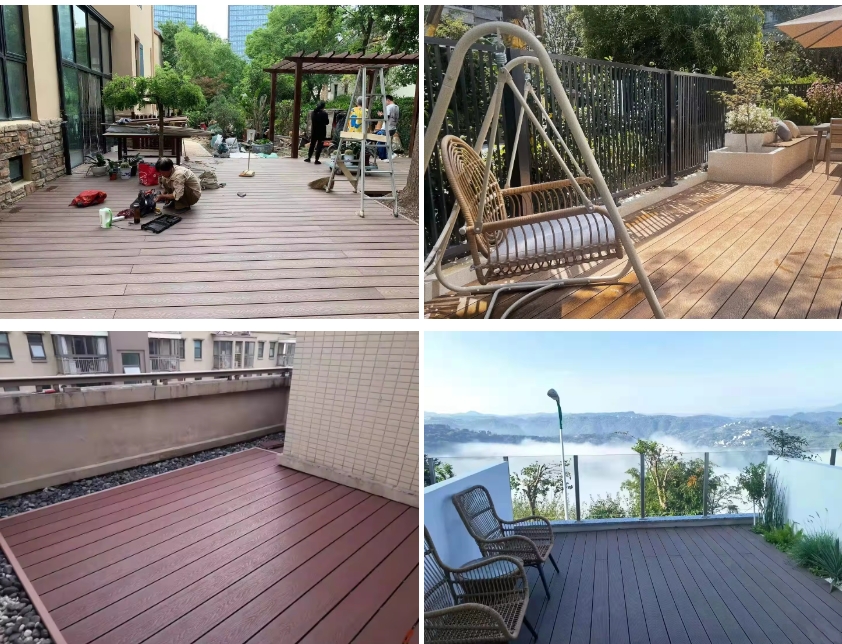

2. Practical application:

Wood-plastic floor paneling can avoid the disadvantages of traditional wooden decorative materials, and there will be no problems such as cracking and deformation during use.

What’s more, WPC is also flame retardant, making it ideal for indoor and outdoor installations. Wood-plastic flooring can not only make up for the shortcomings of traditional materials, but also extend the service life and reduce the application cost of panels.

Final product Application of the final product

| extruder model | Extrude output | main motor power | screw speed | Cooling outside the barrel | screw material | Barrel material |

| SJZS 51/105 | 100-150kg/hour | 18.5kw; AC motor | 38.4 rpm | 400w × 3 wind cooling fan | 38CrMoALA and through high temperature nitriding treatment. Nitriding depth: 0.5-0.6 Hardness (HV): 740-940 Surface roughness ≤ 0.8um | 38CrMoALA and through high temperature nitriding treatment. Nitriding depth: 0.4-0.7 Hardness (HV): 740-940 Surface roughness ≤ 0.8um |

| SJZS 55/110 | 180-280kg/h | 22 kW; AC motor | 38.4 rpm | 400w × 3 wind cooling fan | ||

| SJZS 65/132 | 300-350 kg/h | 37 kW; AC motor | 38.4 rpm | 550w × 3-wind cooling fan | ||

| SJZS 80/156 | 400-450kg/h | 75 kW; AC motor | 40 rpm | 550w × 5 wind cooling fan |