Wood Plastic Composite WPC Machine

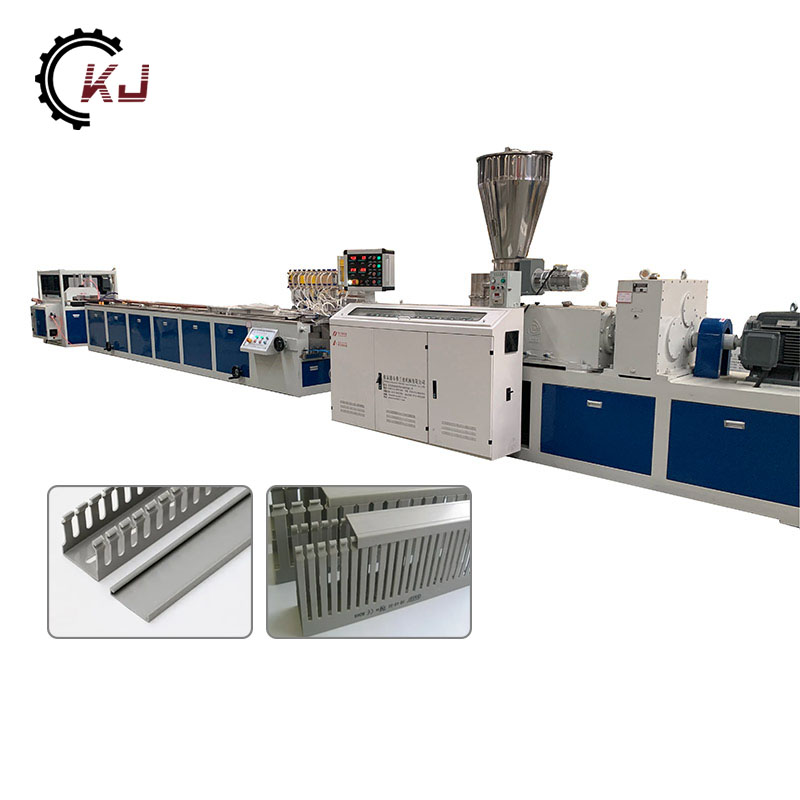

The Wood Plastic Composite WPC Machine is a crucial component of the WPC machine. It combines and melts the wood and plastic materials, forming a uniform mixture. This mixture is then forced through a die to shape it into the desired profile or board. The die is a critical component that shapes the WPC material into the desired profile or board. After exiting the die, the product moves onto a calibration table, which helps in maintaining its shape and dimensions.

Send Inquiry

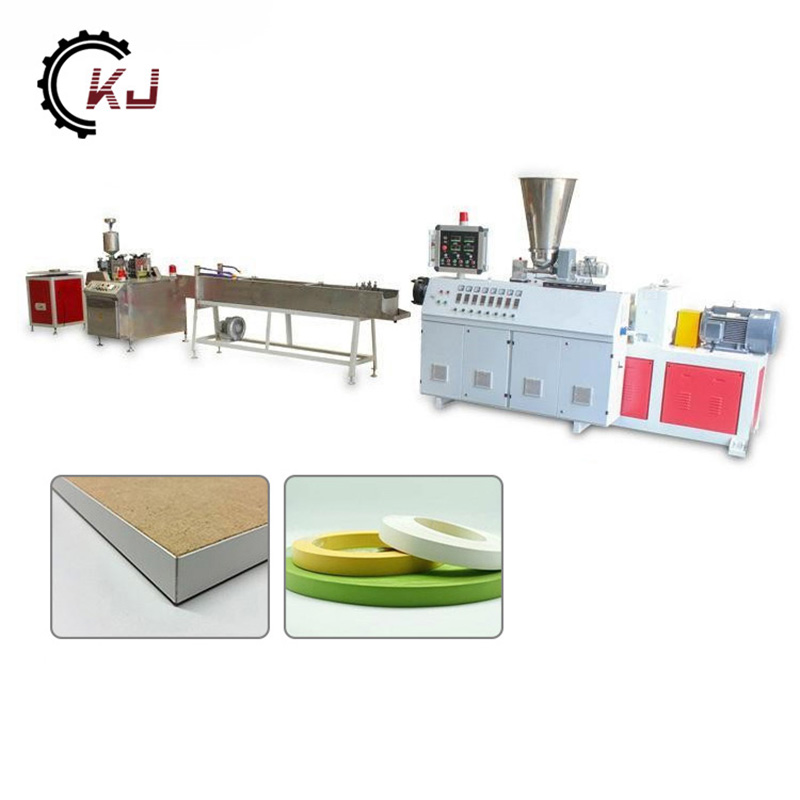

Wood Plastic Composite machine is a type of manufacturing equipment used to produce WPC products. WPC is a composite material made from a combination of wood fiber or wood flour and thermoplastic materials, such as polyethylene, polypropylene, or PVC. These machines are specifically designed to process and shape this composite material into various products, such as WPC boards, profiles, decking, and more.

Application of Wood Plastic Composite WPC Machine

The Plastic PVC Wood WPC Door Panel Making Machine serves the purpose of crafting WPC door panels using a mixture of PVC and wood powder. These WPC hollow panels are versatile, finding applications in both interior and exterior door panels, partitions, windowsills, and more. This technology combines the advantageous traits of both plastic and wood, while simultaneously addressing the limitations of traditional wood materials, including resistance to water, corrosion, pests, aging, static buildup, and fire resistance.

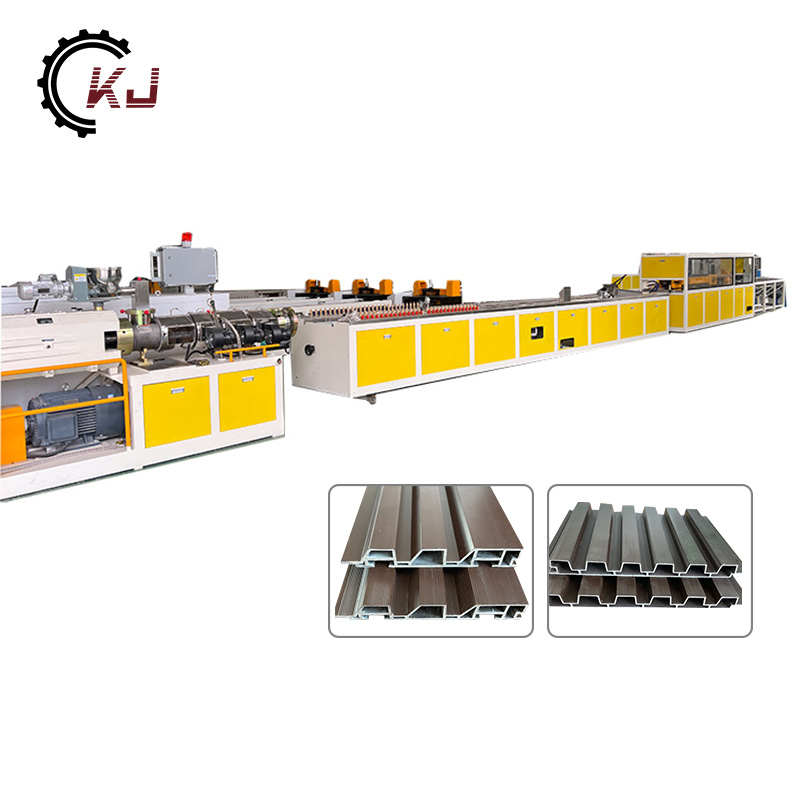

The WPC PVC Door Production Line is designed for the continuous extrusion of WPC/PVC door panels, cladding, and angled boards. The choice of an appropriate double-screw extruder is made based on factors such as the panel's cross-section, intended use, and material density. The production line also comes equipped with essential auxiliary equipment, including a vacuum calibration platform, haul-off machinery, cutting equipment, material reversal platform, and more. This setup allows for the creation of products with diverse specifications using different molds.

The wood working machines can be used for processing the WPC hollow panel into finished WPC doors, such as sanding machine, CNC engraving machine, laminating machine, painting machine, after all processing, you shall get finished WPC doors as below:

Wood Plastic Composite WPC Machine for WPC PVC DOOR MAKING MACHINE

The Wood Plastic Composite WPC Machine includes the below parts:

1.Mixing System in WPC PVC Door Production: Utilizes a high-speed heating and cooling mixing process.

2.WPC PVC Door Manufacturing Feeder and Extruder: Incorporates a conical, double-screw extruder with a high-capacity design tailored for WPC production.

3.Customizable Die and Molding System: Allows mold changes to create doors of different panel sizes.

4.Precision Calibration in WPC PVC Door Production: Employs a vacuum and water cooling method to ensure high-capacity production.

5.Robust Haul-Off Mechanism for WPC PVC Door Production: Features a high-power haul-off device specifically engineered for WPC door manufacturing.

6.Cutting Precision in WPC PVC Door Fabrication: Ensures the cutter is equipped with a high-quality saw for precision cutting.