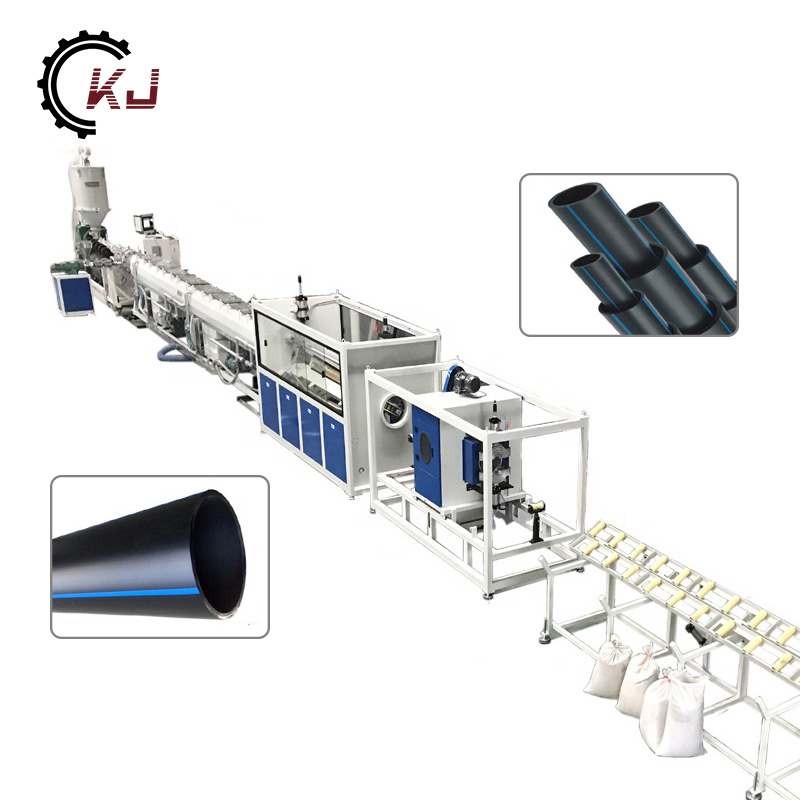

HDPE Corrugated Pipe Extrusion Line

The HDPE Corrugated Pipe Extrusion Line utilizes an extrusion and forming process, offering reliable quality and high efficiency. Double wall corrugated pipe, with its superior wall structure design, stands out among other plastic pipe options. Its lightweight construction not only reduces production costs but also enhances market competitiveness. This type of pipe finds widespread application across various fields, serving as a substitute for concrete and iron pipes. Its popularity stems from its ease of connection, simple installation of accessories, and dependable quality.

Send Inquiry

Double wall corrugated pipe , polyethylene corrugated pipe, corrugated pipe, double wall pipe, are all the names of the pipe consisting of two layers of polyethylene.

The inner layer is fully polished and the outer is corrugated and rippling so that this shape and geometric form results in high resistance in tolerance of all surface and

subsurface pressures, including live or dead load underground. Double wall corrugated pipes are classified into three pressure classes (pressure means the pressure of

exterior load) which are 16- 31.5- 64 kilonewton respectively each of which are used in a particular application in terms of type of soil surface, load pressures from surface and subsurface.

|

Item |

Name |

Qty |

|

1.1 |

Extruder |

one set |

|

1.2 |

Mould |

one set |

|

1.3 |

Corrugate shaping machine |

one set |

|

1.4 |

Winder |

one set |

|

1.5 |

Electrical appliance |

one set |

Why double wall corrugated pipe?

Double wall corrugated polyethylene pipes are highly resistant because of the soil volume and ring stiffness. The inner pressure of these pipes is usually 2 to 4 bars and

hence they cannot be used in the networks under high pressure. In order to connect these corrugated pipes, coupler, washer or extruder welding could be used.

The lifetime of corrugated pipes is approximated to be about 50, 75 and even 100 years which depends on the raw material, conditions of production, storage and maintenance.

Note that in case that the pipe has to be buried and endure the environmental conditions, there are some issues to be considered. As for corrugated pipes, the ph of the soil must be considered.

The corrugated pipe made from polyethylene is being used for almost a decade due to its resilience against subsidence and deterioration, easy installation and its resistance against the movement of soil and pressure.

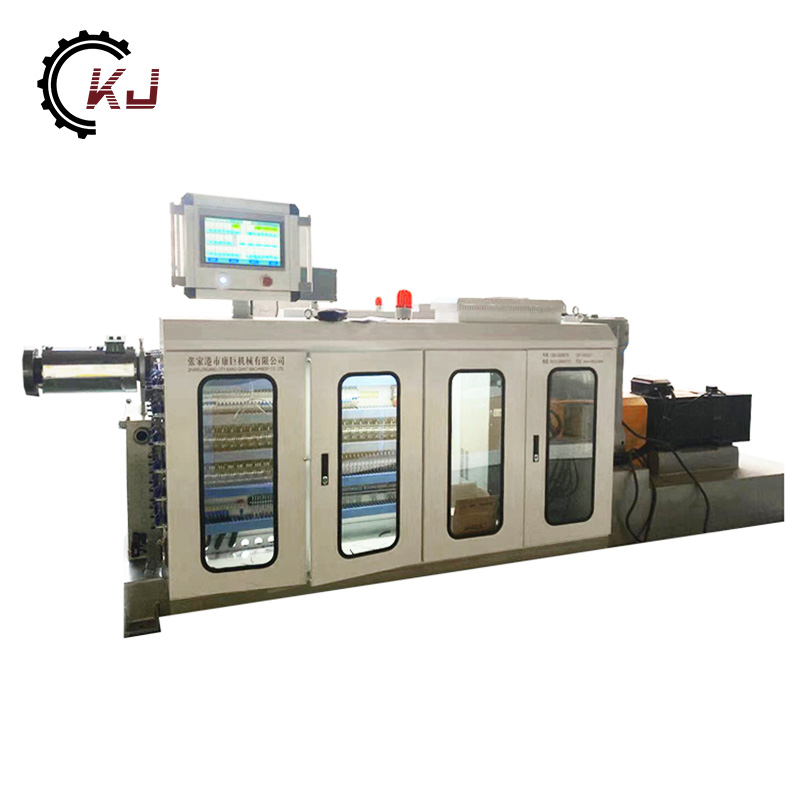

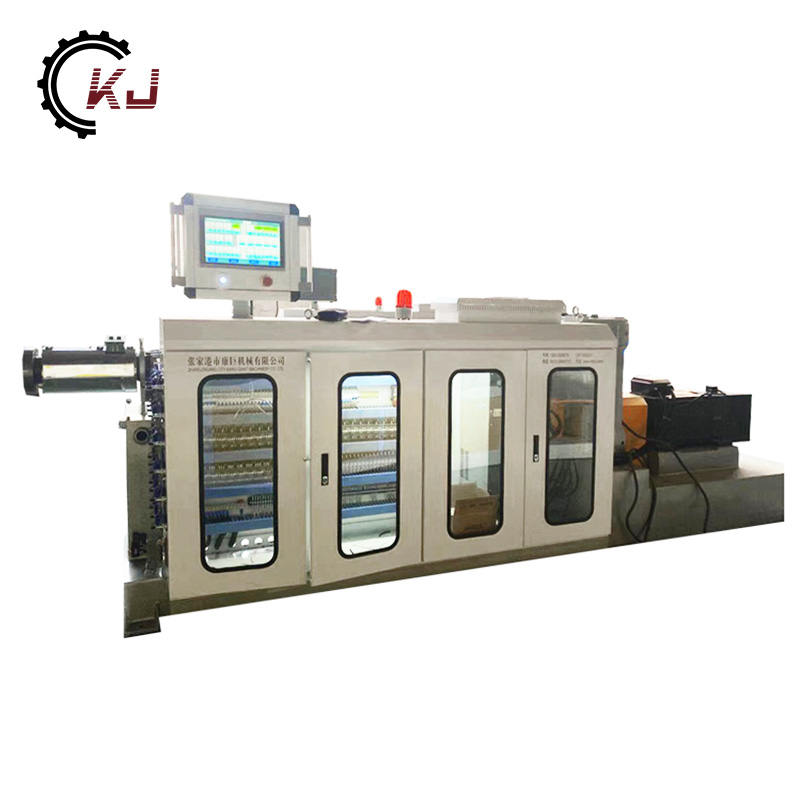

HDPE corrugated pipe extruder This production line can be used to produce corrugated pipes of PE,PP,PVC,EVA continuously,as well as PA corrugated pipes

( by changing different screw L:D).SJDBGZ series plastic single-wall corrugated pipe production line developed by our company adopts gears to run modules and

templates so as to realize water circulating cooling and air cooling of the products,which ensures high-speed molding,even corrugation,smooth inner and outer pipe wall.

Machine list (Plastic PE PA PVC corrugated electrical conduit making machine)

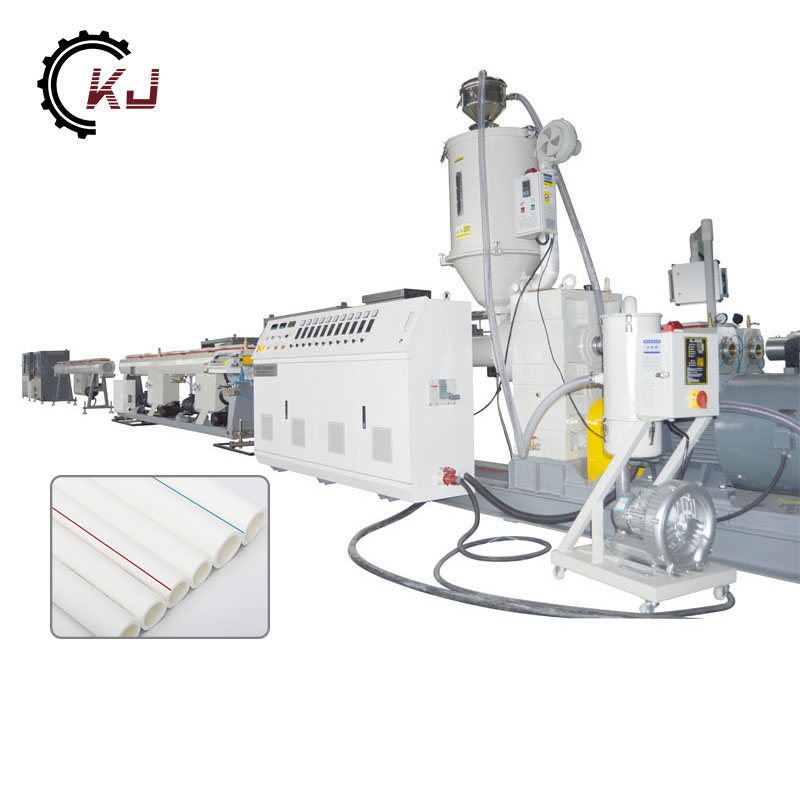

HDPE Corrugated Pipe Extrusion Line Application:

1) Plastic single-wall corrugated pipes have feathers of high temperature resistance,resistant to corrosion and abrasion,high intensity,good flexibility,etc.

2) They are widely used in fields of auto wire,electric thread-passing pipes,circuit of machine tool,protective pipes of lamps and lanterns wire,tubes of air conditioner , vacuum cleaner and washing machine,etc.

3) These corrugated pipes are especially used as wires of the up-market cars.