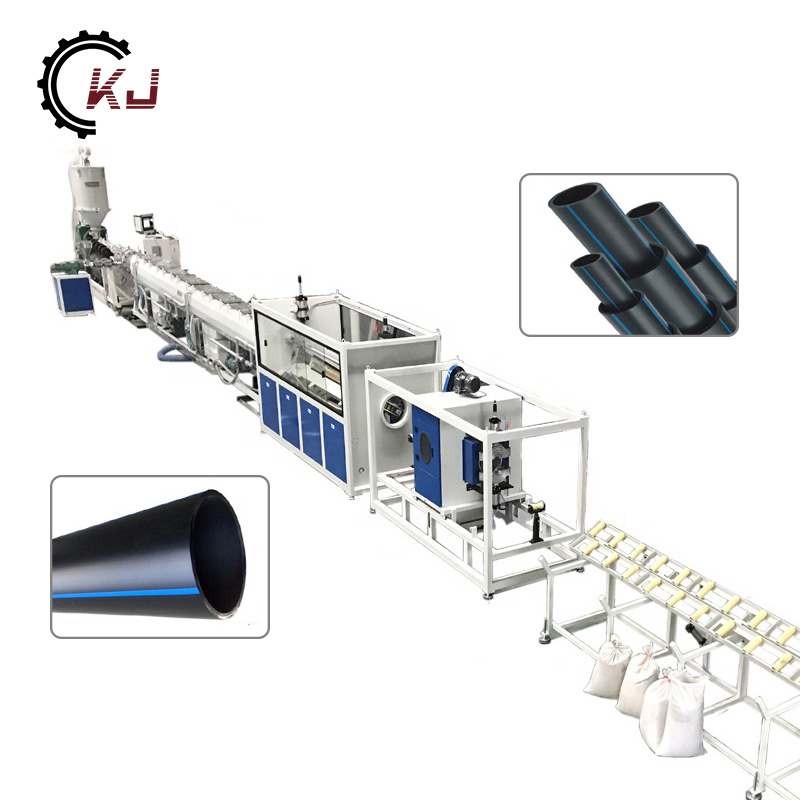

HDPE Pipe Machine

Kangju Manufacturer's HDPE Pipe Machine is primarily designed for the production of large-diameter HDPE/MDPE pipes. These pipes exhibit several outstanding characteristics, including resistance to heat, aging, and environmental stress cracks, along with high mechanical strength and good creep resistance.

Send Inquiry

PE Pipe.

■ Superior hygienic qualities: No heavy metal salt stabilizers are added during the processing of PE pipes, ensuring the material is non-toxic, free from scaling, and resistant to bacterial growth. This eliminates the potential risk of secondary pollution in urban drinking water.

■ Remarkable corrosion resistance: Apart from a few strong oxidizers, PE pipes can withstand a wide range of chemical media without suffering electrochemical corrosion.

■ Extended service life: PE pipes can be safely used for over 50 years when operated within their rated temperature and pressure ranges.

■ Enhanced impact resistance: PE pipes exhibit excellent toughness and high impact resistance, allowing heavy objects to pass through the pipe without causing any damage or breakage.

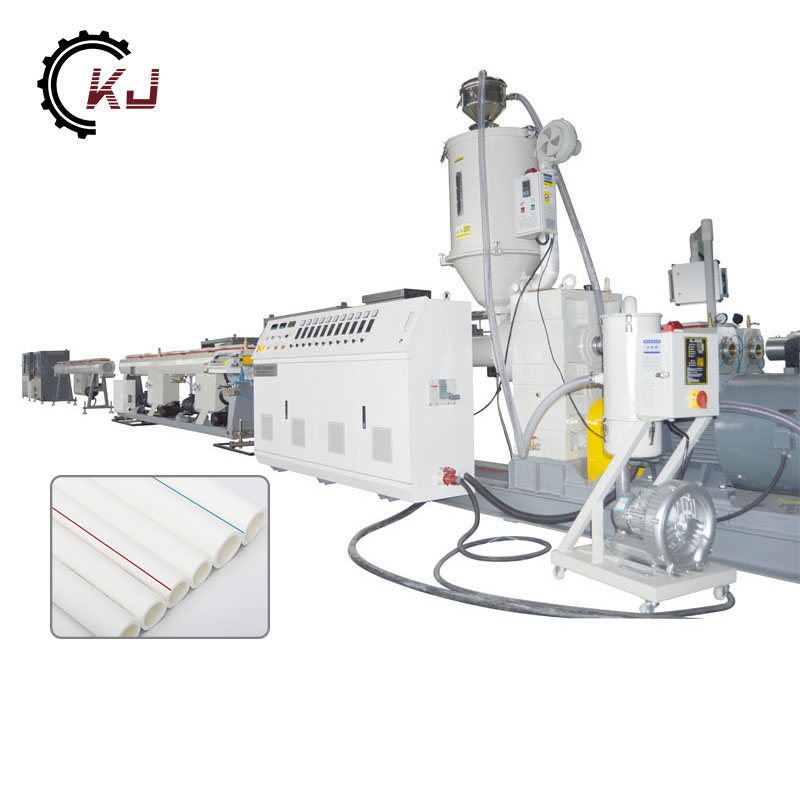

The HDPE Pipe Machine is primarily designed for manufacturing large-diameter HDPE/MDPE pipes. These pipes possess numerous outstanding qualities, including heat resistance, aging resistance, exceptional mechanical strength, resilience to environmental stress cracks, and good creep resistance. As a result, they are highly preferred for gas conduits in ductwork systems connecting cities and suburbs, as well as for water supply in urban areas.

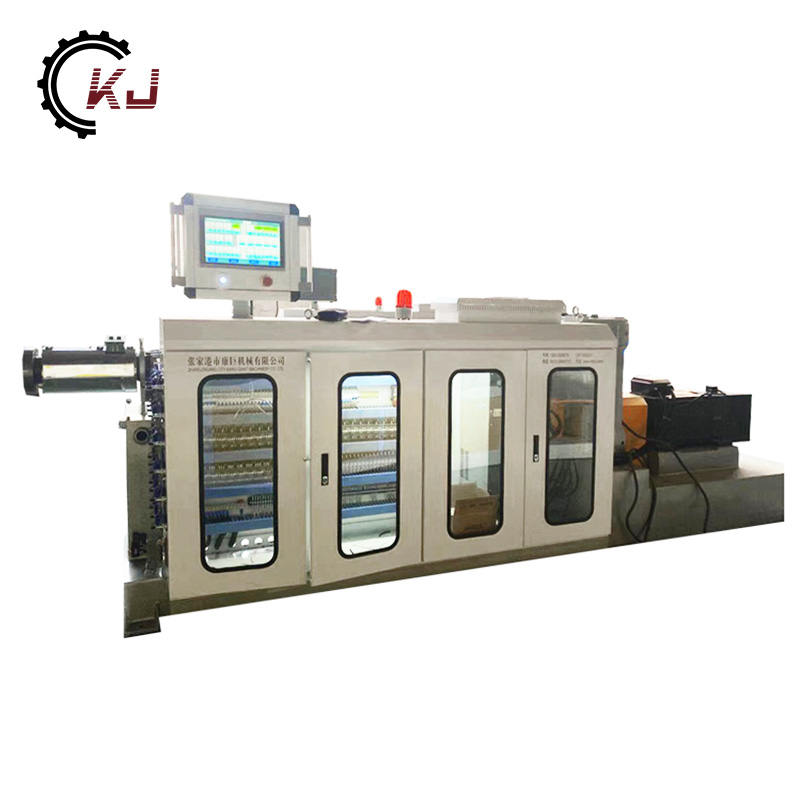

The machine consists of several key components: an extruder, a co-extruder, a pipe die-head, vacuum cooling water tanks, a haul-off machine, a cutting machine, and a stacker. The extruder and haul-off machine are synchronously controlled through frequency conversion. The haul-off machine comes in various configurations, including 2-claw, 3-claw, 4-claw, 6-claw, 8-claw, and 12-claw types. The entire production line is renowned for its reliable performance and efficiency.

Depending on customer requirements, HDPE pipes can be produced as single-layer or composite multi-layer pipes, with the option to add an online measurement control system.