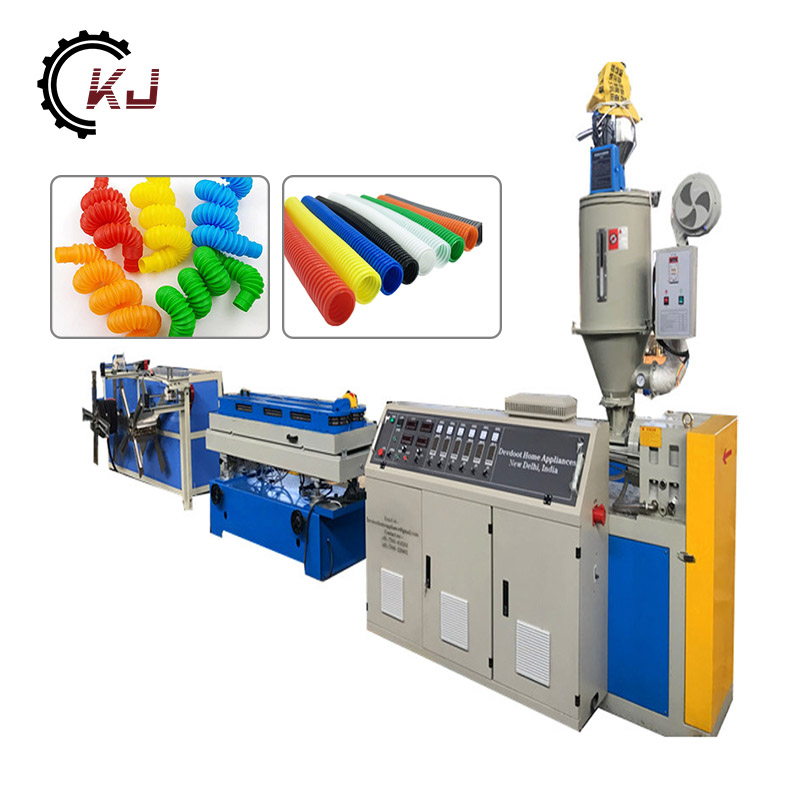

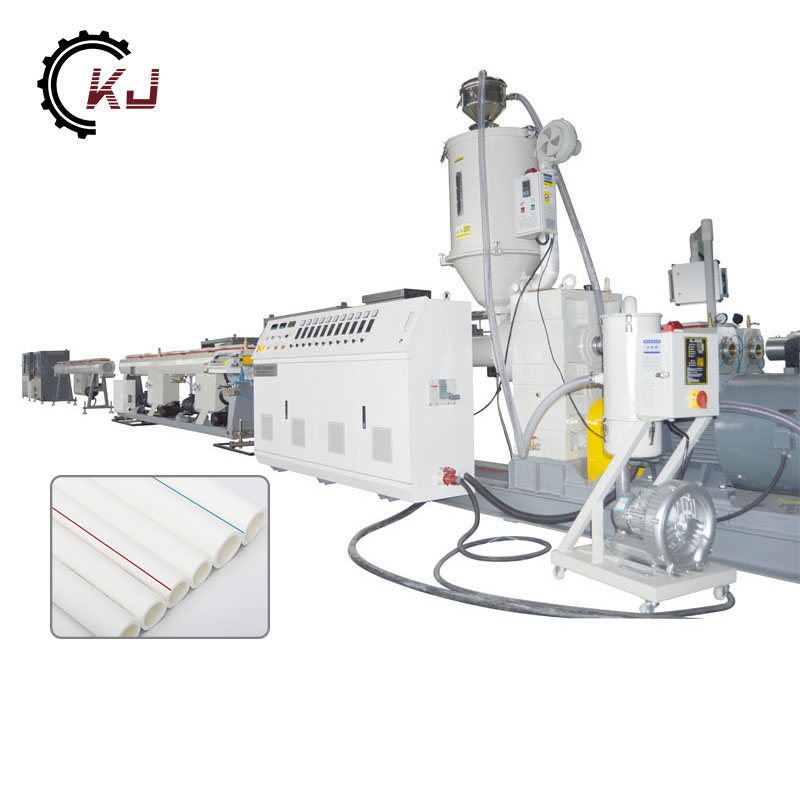

PE PP PVC Single Wall Corrugated Pipe Make Machine

Mainly use SJ-45 extruder or SJ-65 extruder, which can keep a stabile output and save the energy. The SJ-45 PE PP PVC Single Wall Corrugated Pipe Make Machine for making 9-32mm diameter corrugated pipe, and SJ-65 extruder for making 32-110mm. The L/D can be different when you need different output. The max stable output can reach 120kg/h.

Send Inquiry

Description of Single Wall Corrugated Pipe Make Machine:

1. Single wall corrugated pipe machine uses PVC, PP, PE as raw material to produce single-wall corrugated pipe for protection electric wire.

2. Through the corresponding mould and setting machine, the products can be smooth evenly both internal and external.

3. Application of products: Cable threading pipe, washing machine drain pipe, vacuum tubes, ventilation drain pipe, etc.

Main Technical Parameter---PE PP PVC Single Wall Corrugated Pipe Make Machine:

|

Extruder Model |

SJ50 |

SJ65 |

|

Screw diameter (mm) |

50 |

65 |

|

Ration of L/D |

30:1 |

30:1 |

|

Pipe diameter range |

9-32 |

32-110 |

|

Pairs of modules |

64 |

72 |

|

Line speed (m/min) |

8-12 |

20-25 |

|

Module cooling way |

Air-cooled |

Water-cooled |

|

Pipe cooling way |

Air-cooled |

Air-cooled |

|

Total install powder (kw) |

50 |

70 |

Configuration List:

|

Automatic vacuum feeder |

1 set |

|

Dryer |

1 set |

|

Single-screw extruder |

1 set |

|

Corresponding single-wall corrugated pipe extruding die |

1 set |

|

Single-wall corrugated pipe molding machine |

1 set |

|

Coiling machine |

1 set |

|

Meter counter |

1 set |

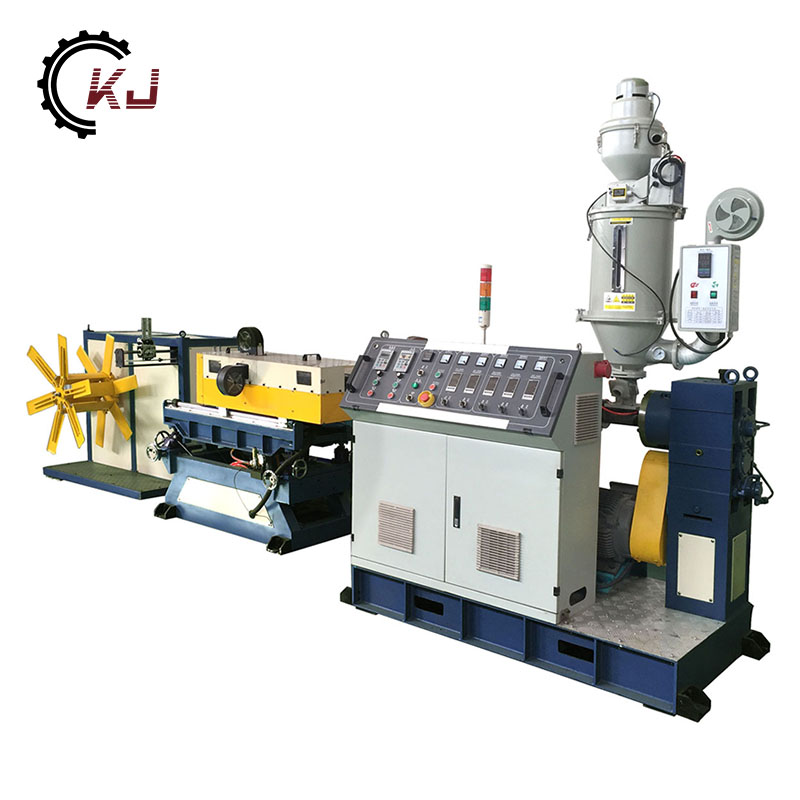

Images of Single Wall Corrugated Electric Wiring Pipe Make Machine:

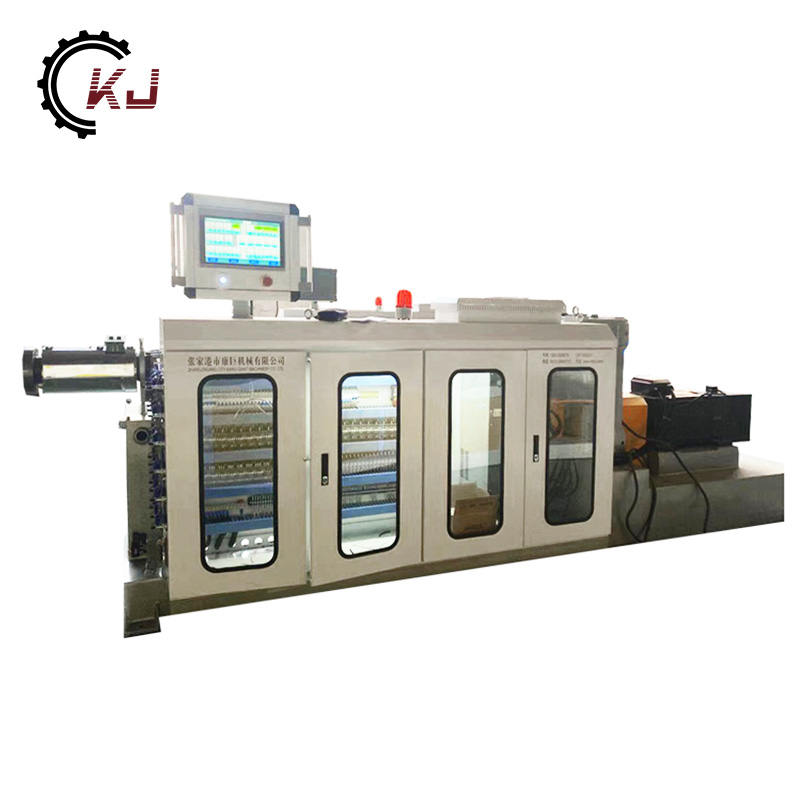

1. Extruder:

Mainly use SJ-45 extruder or SJ-65 extruder, which can keep a stabile output and save the energy. The SJ-45 extruder for making 9-32mm diameter corrugated pipe, and SJ-65 extruder for making 32-110mm. The L/D can be different when you need different output. The max stable output can reach 120kg/h.

2. Corrugated Pipe Molding Machine:

This PE PP PVC Single Wall Corrugated Pipe Make Machine is used to shape the corrugated pipe. The mould can be discharged and changed. Corrugated pipe diameter is decided by the mould, so if you want to process different diameter, you should change differnet mould. Our factory can also provide you with the mould.

3. Coiling Machine:

This PE PP PVC Single Wall Corrugated Pipe Make Machine is used to reel in and packing of corrugated pipe. With electric control system it can control reeling speed accurately. And it can also control the size of reeling. It is very convenient for discharging. This machine also is widely used in other soft pipe making lines.

Applications: