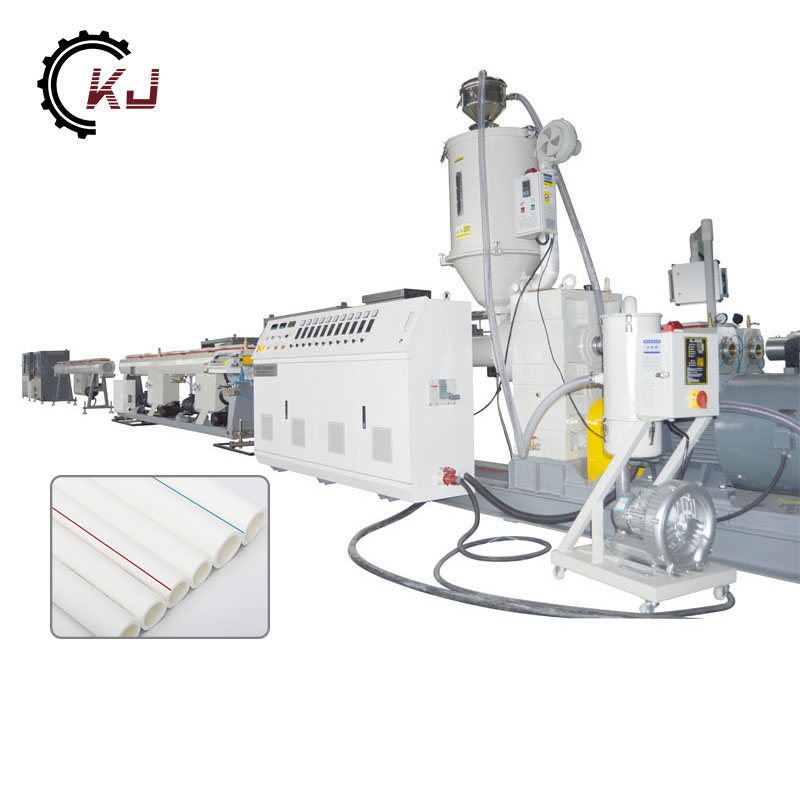

polyethylene plastic PE pipe making machine

As the professional manufacturer, we would like to provide you high quality polyethylene plastic PE pipe making machine.

Send Inquiry

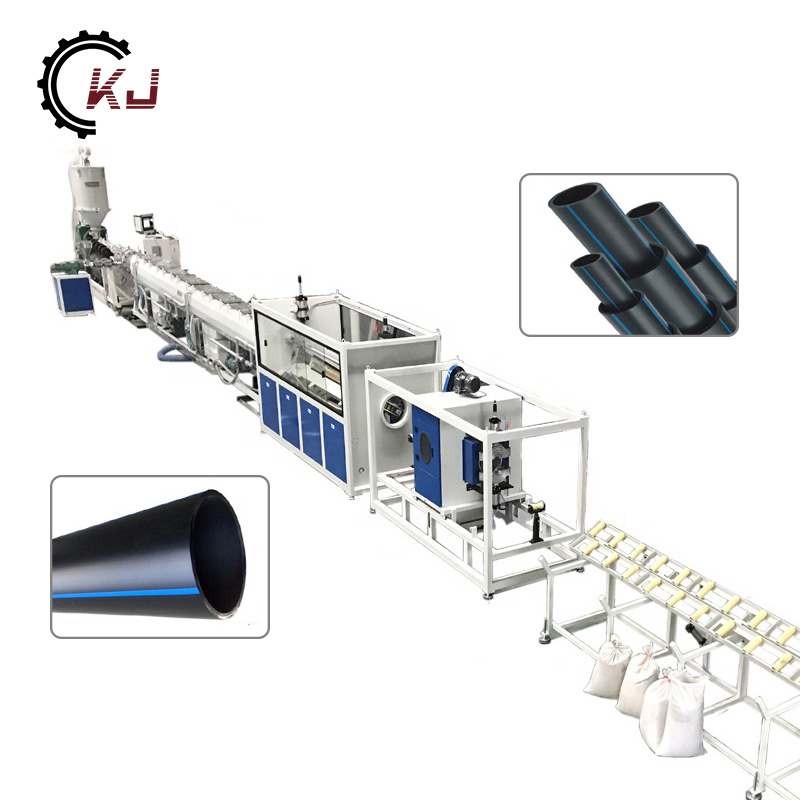

Pe pipe production line

Process flow

Raw Materials + Additives ; Mixing; Vacuum Feeder; Hopper Dryer; Single Screw Extruder; Color Coded Extruder; Mold and Calibrator; Vacuum Forming Machine; Cooling tank; Tractor; Cutting machine; Unloading rack.

HDPE series plastic pipe production lines are mainly used to produce waste supply and drainage pipes in fields such as agriculture and construction.

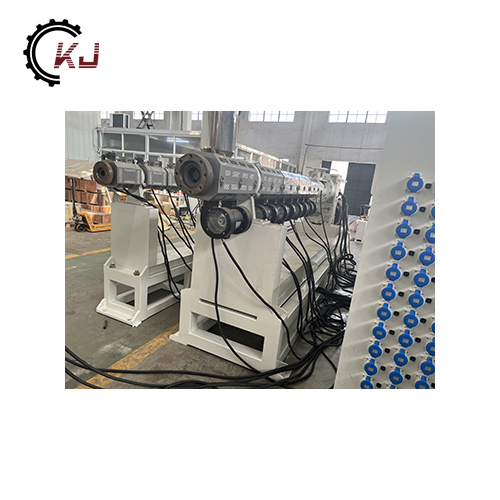

The polyethylene plastic PE pipe making machine consists of extruder, mold, vacuum calibration tank, and hauling unit. Cutting units, stackers, etc.

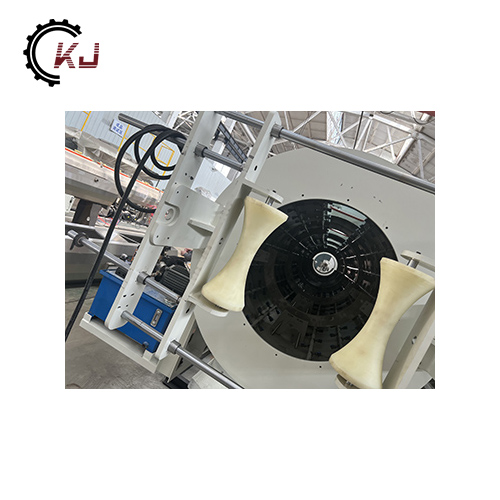

The single-screw extruder and hauling unit adopt the famous A/C frequency conversion speed control device, and the vacuum pump and water pump are

of famous brands. The hauling units include double-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, ten-claw type, twelve-claw type, etc.

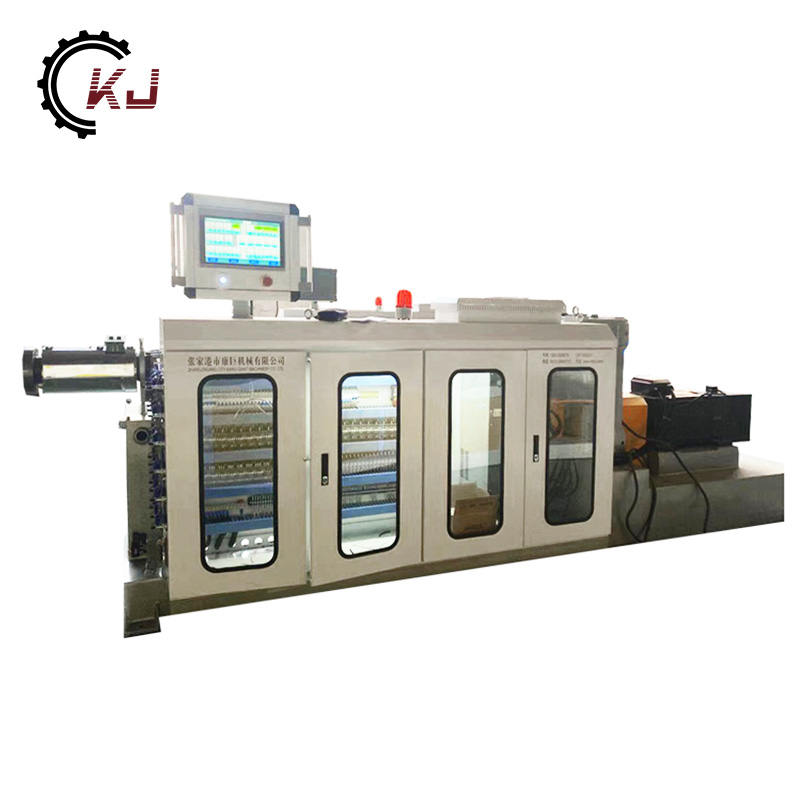

Dust-free cutting machines, saw blade cutting machines or planetary cutting machines can be used, and the performance of the unit is reliable.

The production efficiency is high by using special equipment. It can also produce PP, PE, ABS, PPR, PEX, silicon core tubes, etc.

The planetary cutting machine is automatically controlled by a computer and has the advantages of simple operation and reliable performance.

It has reached the international advanced level.

| model | PE-16/63 | PE-20/110 | PE-50/160 | PE-75/250 | PE-110/315 | PE-200/450 | PE-315/630 | PE-400/800 |

| Pipe diameter | 16-63mm | 20-110mm | 50-160mm | 75-250mm | 110-315mm | 200-450mm | 315-630mm | 400-800mm |

| maximum output | 150kg/h | 200kg/h | 350kg/h | 350kg/h | 350kg/h | 450kg/h | 850kg/h | 850kg/h |

| productivity | 1-15 meters/minute | 1.2-12m/min | 0.6-8m/min | 0.5-4m/min | 0.4-3.7 meters/minute | 0.3-3 m/min | 0.2-2 m/min | 0.1-1 m/min |

| extruder model | SJ-65/30 | SJ-65/33 | SJ-75/33 | SJ-75/33 | SJ-75/33 | SJ-90/33 | SJ-120/33 | SJ-120/33 |

| Install power supply | 85kW | 110kW | 125kW | 180kW | 260kW | 325kW | 480kW | 600 kilowatts |

| center height | 1000mm | 1000mm | 1000mm | 1000mm | 1100mm | 1100mm | 1200mm | 1300 |

| Installation area | 35x 3.0x2.0 meters | 38*3.1*2.2 meters | 38*3.1*2.2 meters | 40*3.2*2.4 meters | 42*3.2*2.4 meters | 52*3.3*2.6 meters | 60*3.5*2.8 meters | 68*3.6*3.0 meters |