China Fence Wall Panel Post Making Machine Manufacturer, Supplier, Factory

Kangju is a professional manufacturers and suppliers in China. Our factory provides Plastic Recycling Machine, Plastic Pulverizer Machine, Plastic Pelletizing Machine, etc. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. We take high quality, reasonable price and perfect service.

Hot Products

HDPE MBBR Filter Media Making Machine

MBBR Carrier media serves as a microbial carrier in the MBBR process, primarily aiming to offer an ideal growth environment for microorganisms. You can confidently purchase the HDPE MBBR Filter Media Making Machine from Kangju factory without any hesitation.Wood plastic composite products manufacturing machine

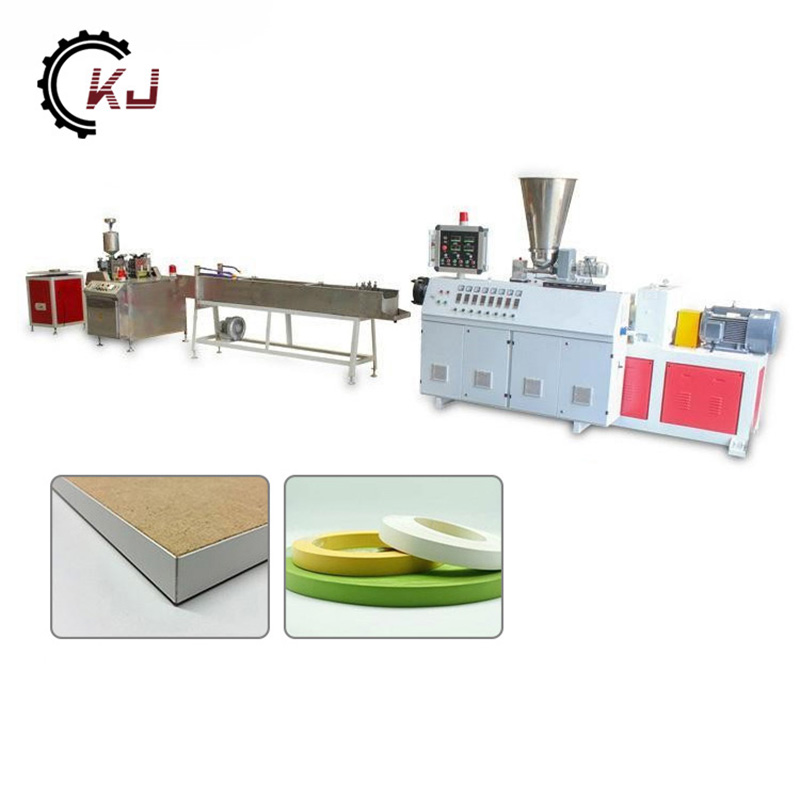

Wood plastic composite products manufacturing machine Wood-plastic floor paneling can avoid the disadvantages of traditional wooden decorative materials, and there will be no problems such as cracking and deformation during use. What’s more, WPC is also flame retardant, making it ideal for indoor and outdoor installations. Wood-plastic flooring can not only make up for the shortcomings of traditional materials, but also extend the service life and reduce the application cost of panels.Wood-Plastic Composite Panel Production Line

Kangju Factory offers a Wood-Plastic Composite Panel Production Line specifically designed for crafting outdoor applications such as wood-plastic paving, fences, columns, pallets, floors, chairs, and wall panels. This comprehensive extrusion line comprises a conical twin-screw extruder, calibration platform, pulling and cutting machine equipped with a vacuum device, and a product stacker. Through a series of processes including mixing, granulation, extrusion, embossing, sanding, and brushing, the resulting PE WPC profiles mimic the appearance and texture of natural wood, offering an exceptional alternative.PE Pipe Sleeve with Double Water Ring

Sizing sleeves play a key role in the production process of PE Pipe Sleeve with Double Water Ring. It is not only responsible for effectively cooling the tube blank to prevent it from being deformed or damaged during subsequent processing, but also ensuring that the outer diameter of the tube blank reaches the predetermined standard size and ensuring the consistency of product quality.wood plastic panel making machine

wood plastic panel making machine Polypropylene polyethylene wood-plastic composite wood-plastic profile extrusion line is used to make outdoor wood-plastic paving, fences, columns, pallets, floors, chairs, wall panels, etc. The extrusion production line includes a conical twin-screw extruder, a calibration platform, a pulling and cutting machine with a vacuum device, and a product stacker. Through mixing, granulation, extrusion, embossing, sanding, brushing and other processing, PE WPC profiles can look and feel similar to natural wood.PET Sheet Extrusion Line

The screw adopts the parallel twin-screw design, which is specially designed for the PET, with venting, uniform plasticization, oblique three-roll calender design and L-type calender design. The roller temperature can be adjusted by the mold temperature machine, and the product has good toughness. PET Sheet Extrusion Line has high transparency and pre-coated silicone oil device to ensure the release of the sheet during the secondary processing. The thickness is measured by the dial gauge, and the winding is automatically tensioned.

Send Inquiry

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy