Home

>

Products > Plastic Extruders

> Plastic Pipe Production Line

>

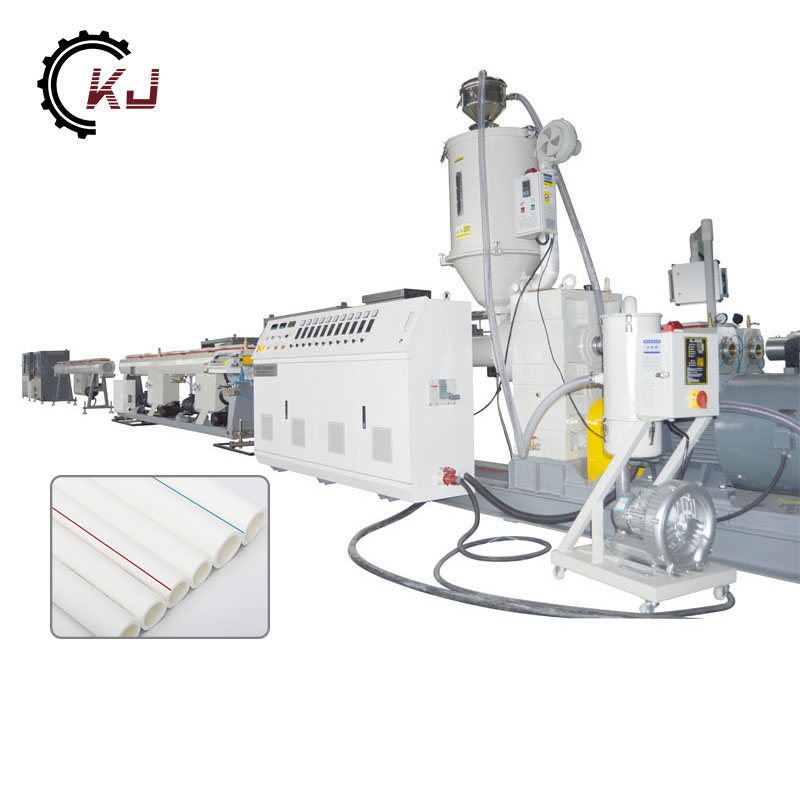

PVC Double-Wall Corrugated Pipe Making Machine Line

PVC Double-Wall Corrugated Pipe Making Machine Line

We cordially invite you to visit Kangju factory, where you can purchase the latest, competitively priced, and top-quality PVC Double-Wall Corrugated Pipe Making Machine Line. We are eager to establish a successful partnership with you.

Send Inquiry

Product Description

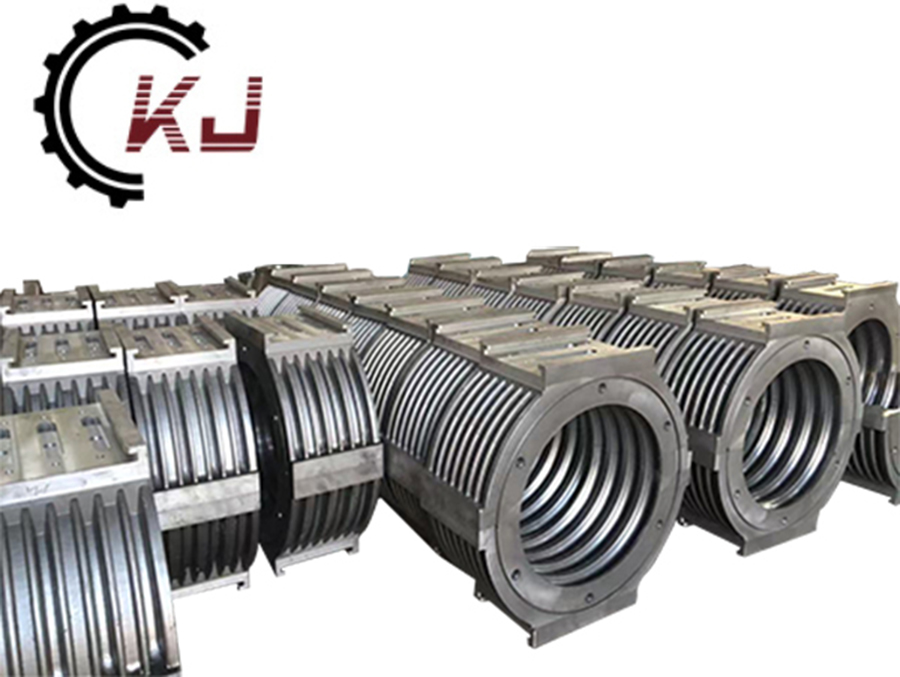

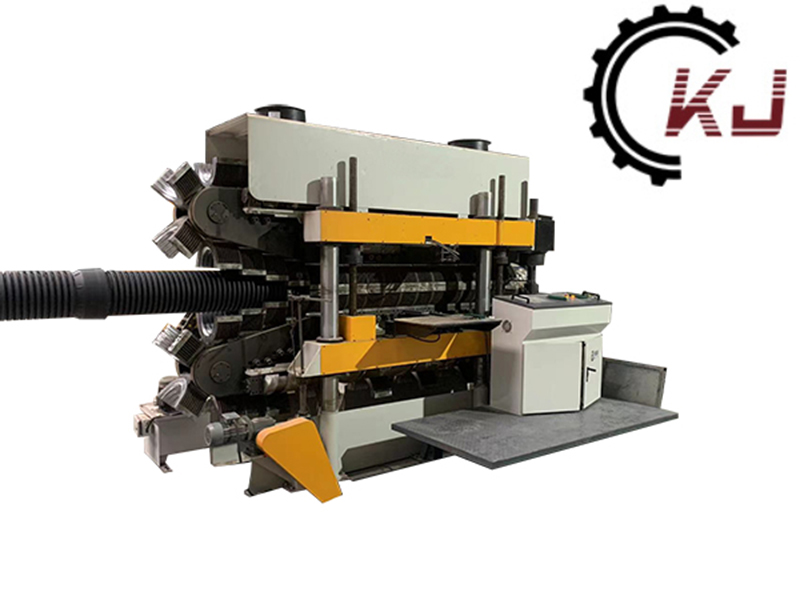

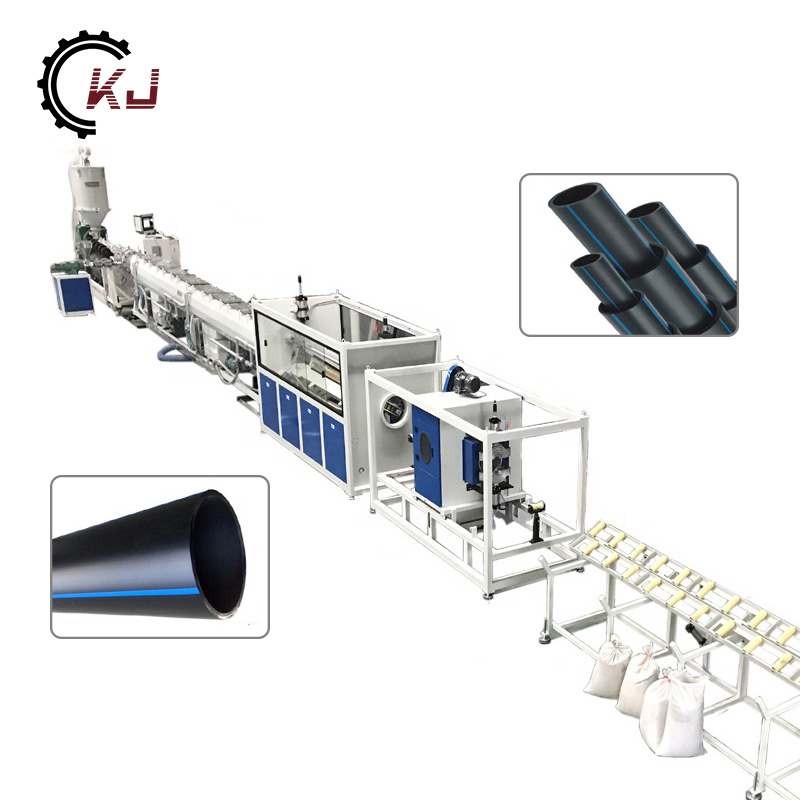

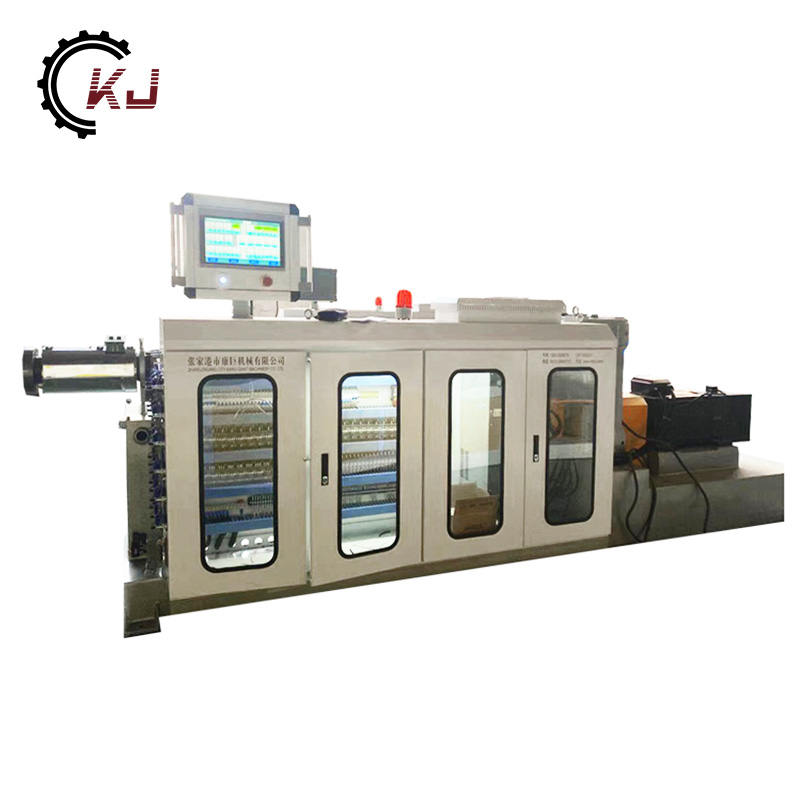

PVC double-wall corrugated pipes find widespread applications in diverse areas, including municipal renewal projects, construction of buildings, drainage systems for industries and agriculture, water-saving irrigation techniques in agriculture, sewage treatment projects, and more. Our PVC Double-Wall Corrugated Pipe Making Machine Line, designed with expertise, employs direct extrusion (co-extrusion) molding technology and is operated by Siemens' advanced human-machine interface control system. This machine line boasts a high level of automation, exceptional output, reliable quality, and stable performance, making it a preferred choice among both domestic and international clients.

| PVC Double-Wall Corrugated Pipe Making Machine Line | |||

| Pipe size | type | Extruder | Output |

| 50-160mm | Single wall | SJ75/33 | 150-250kg/h |

| Double wall | SJ75/33& SJ65/33 | 350-400kg/h | |

| 200-800mm | Double wall | SJ120/33&SJ90/33 | 600-1000kg/h |

| 800-1200mm | Double wall | SJ90/38&SJ75/38 | 1200-1500kg/h |

| PVC corrugated pipe extrusion line | |||

| Pipe size | type | Extruder | Output |

| 50-1600mm | Single wall | SJZ55/110 | 150-200kg/h |

| Double wall | SJ55/110&SJZ51/105 | 200-300kg/h | |

| 200-500mm | Double wall | SJZ80/156&SJZ65/132 | 500-650kg/h |

Hot Tags: PVC Double-Wall Corrugated Pipe Making Machine Line, Manufacturer, Supplier, China, Factory, Low Price, Buy, Quality

Product Tag

Related Categories

Plastic Panel Sheet Extrusion Machine Line

Plastic Pipe Production Line

WPC PE PVC Profile Extrusion Machine Line

SPC LVT Flooring Production Line

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy