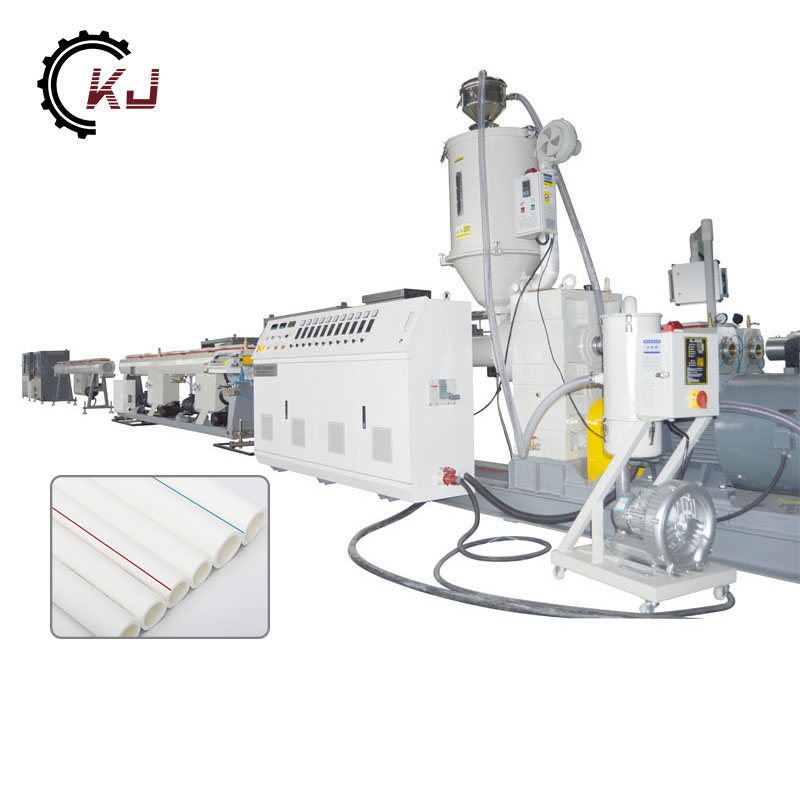

PVC-O UPVC pipe producing making machine

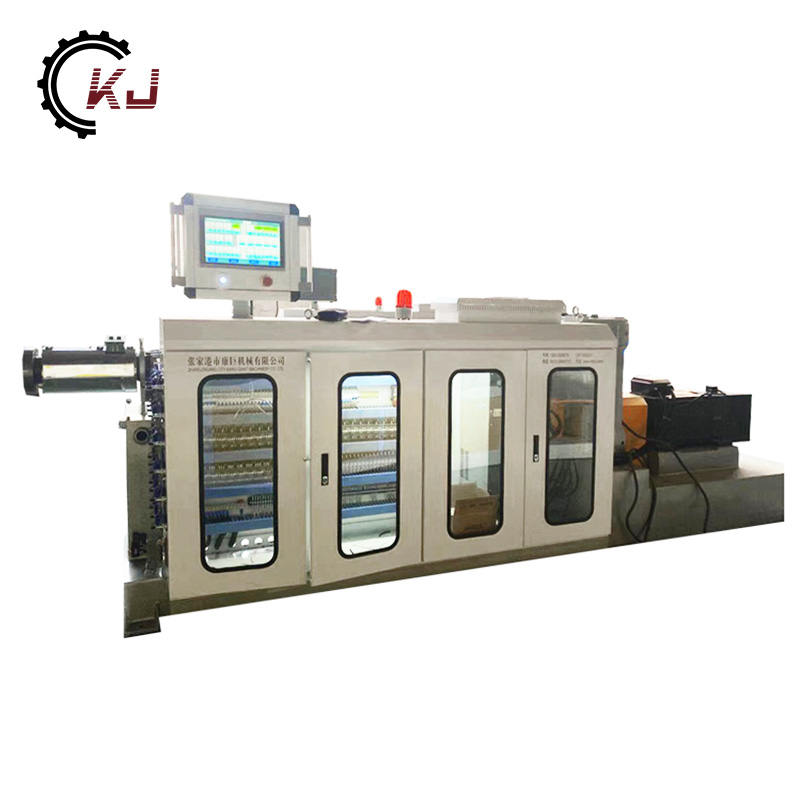

The PVC-O pipe is a pipe produced by the bidirectional stretching process.The raw material formulation of the pipe is basically the same as that of the ordinary PVC-U pipe. The perfomance of the pipe produced by this proces is greatly improved compared with PVC-U pipe.You can rest assured to buy PVC-O UPVC pipe producing making machine from our factory and we will offer you the best after-sale service and timely delivery.

Send Inquiry

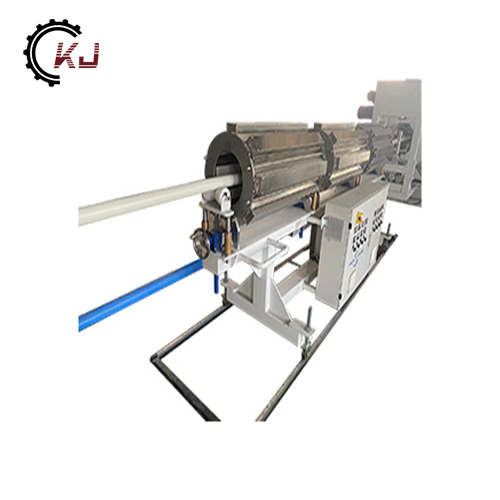

This PVC-O UPVC pipe producing making machine use newest techology to make plastic pipes. With special biaxial stretching technology, it can largely reduce the material cost for pipe production, more than 70%. It is become more and more popular now days.

Technical data

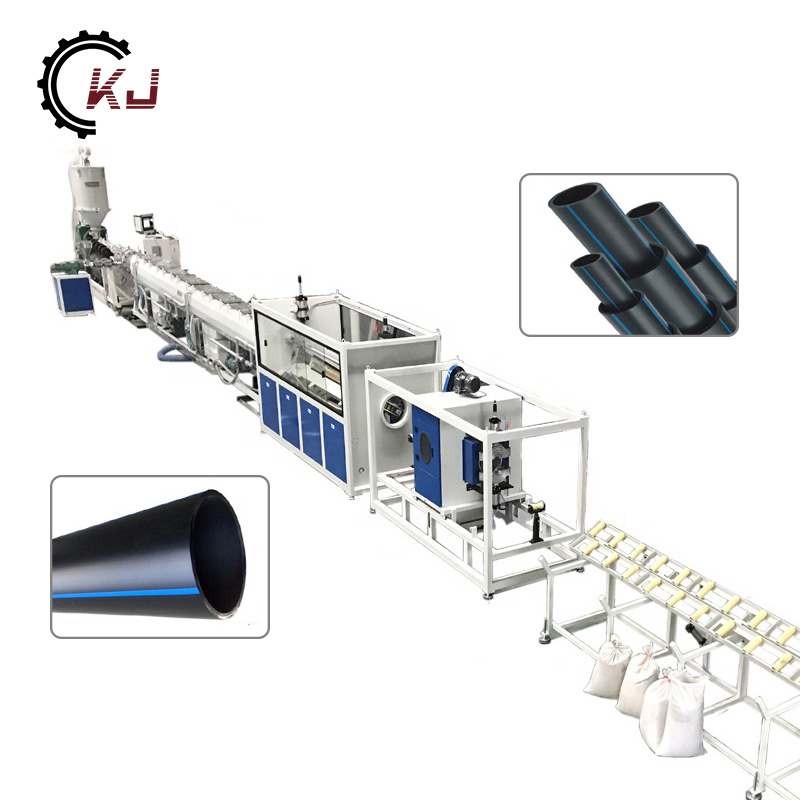

Model/data Pipe diameter Extruder model Speed Max capacity

FP250 90-250mm LSZ65 1.5-8m/min 300kg/h

FP315 110-315mm LSZ75 0.5-5m/min 500kg/h

FP630 400-630mm LSZ92 0.1-2m/min 800kg/h

PVC-O pipe is the latest evolutionary form of PVC pipe pipe. By using a special orientation process (biaxial stretching technology), stretching and radial stretching, so that the long-chain PVC molecules in the pipe biaxially arranged in order to obtain high strength, high toughness, high impact resistance, crack resistance of the new PVC pipe.

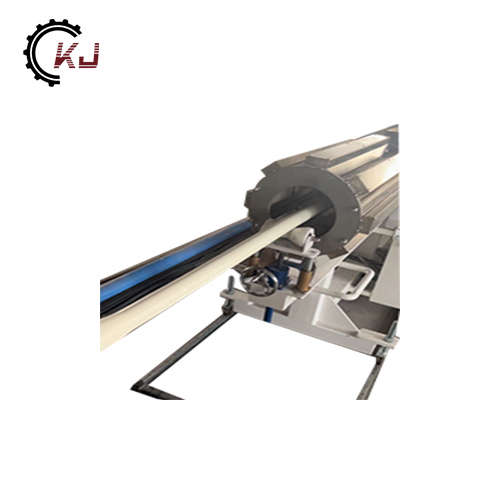

The stretching orientation process of polymer materials is the process of the molecules arranged from disordered to ordered under the action of external force under the condition of temperature between the glass transition temperature and the melting temperature (usually near the softening point). Biaxial stretching is a process in which a material is biaxially stretched to make the strength perpendicular to the the stretched surface of the biaxial stretching that superimposed on the strength of the stretched surface direction, thereby increasing the strength of the material in the direction of the stretched surface.

Compare to normal PVC pipes, the pipe wall thickness of PVC-O is very thin, but it can endure high pressure. With PVC-O pipe making machine, the client can largely save the material cost.

The PVC-O pipe is a pipe produced by the bidirectional stretching process.The raw material formulation of the pipe is basically the same as that of the ordinary PVC-U pipe. The perfomance of the pipe produced by this proces is greatly improved compared with PVC-U pipe, the impact resitance of the pipe is improved by about 4 times, the toughness i stl maintained at minus -20" C, and the wall thickness of PVC-U pipe is reduced by alf under the same pressure. About 47% of the raw material is saved, and a thinner wall thickness means that the pipes water conveying capacity is stronger, the pipes are lighter and more convenient to install, and the transportation cost is lower.